Substation robot inspection comprehensive

business background:

In recent years, with the rapid development of my country's power grid, the number of substations has increased sharply. At the same time, the insufficient number of substation attendants has caused many problems in substation management. Through the patrol robot wifi module communication system to assist or even replace the manual inspection of substation equipment, it can effectively reduce the potential safety hazards, so as to achieve a more reliable inspection of the equipment.

Intelligent robots for substation inspection are mainly used for line inspection and maintenance. The wifi module communication system of intelligent robots for substation inspection can perform inspections in long-distance or outdoor high-voltage dangerous environments through remote control by substation staff, and can find electrical equipment in time If there are any abnormal phenomena such as defects, foreign objects hanging, etc., it will automatically alarm or carry out pre-set fault handling. Its use can really play the role of downsizing and increasing efficiency of substation maintenance lines, and can accelerate the work process of substation inspection lines.

Industry Status:

Although robots have been widely used in power inspections at this stage, the lack of wireless communication technology still makes intelligent robots still have some problems in power inspections, which are embodied in the following two aspects.

1. The inspection robot is small, and the antenna and equipment installation are limited.

2. On-site electromagnetic signals are more complicated, which will interfere with the transmission signal of the inspection robot.

An Introduction:

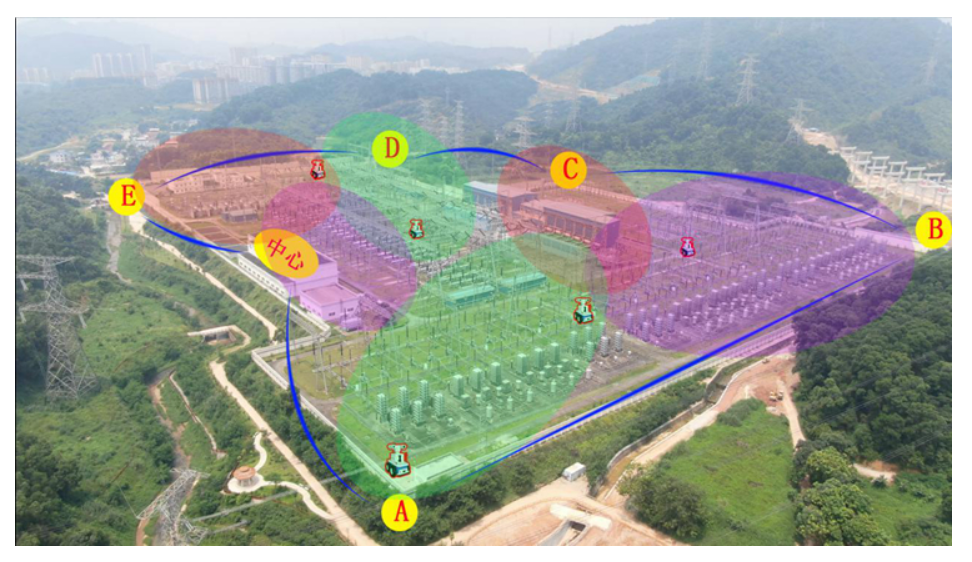

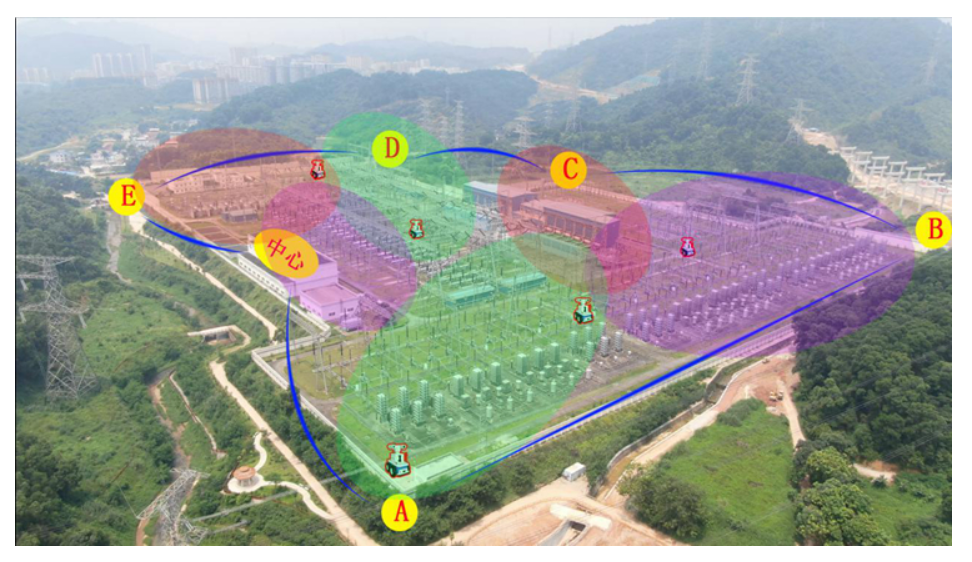

The Wi-Fi coverage system ABCDE deployed in the National Grid substation represents the different edge corners of the substation distribution. We use long-distance Wi-Fi to transmit these points and the center wirelessly, and then we can not separate the mesh group of the wireless signal at each point. Network coverage, basically achieve global coverage.

The inspection robot adopts single-mode wireless transmission equipment, which is integrated with the robot. If you need to transmit control data or sensor data, you can choose a serial port module. Through this set of programs, the following problems can basically be solved.

1. Transmission of vehicle video signal.

2. Global (active area) wireless signal coverage.

3. Solve the problem that the signal can be switched freely when the vehicle is traveling in different areas.

4. Potential problem-solving: A center can control the vehicle forward through the interconnection of on-site wireless signals (customization is required, using device serial data or industrial control modbus protocol, etc.).

Industry application:

Through the long-distance WiFi Mesh self-organizing network, the national grid substation inspection system can achieve the effect of all-round stable transmission, which greatly improves the efficiency of substation inspection. In addition, this inspection robot wifi module communication system can also be applied to unmanned vehicles, unmanned ships and other fields, and plays an extremely important role in the communication of modern intelligent control equipment.